| Availability: | |

|---|---|

| Quantity: | |

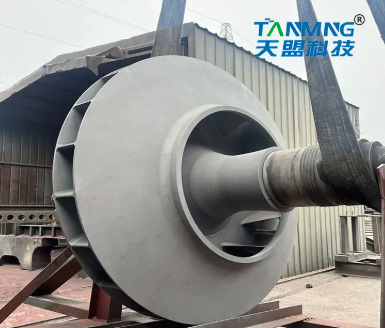

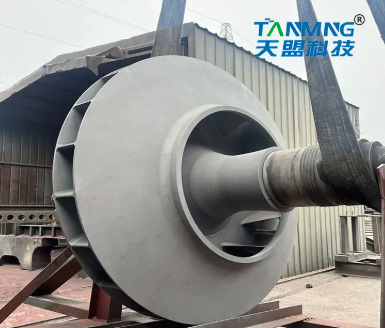

Fan impeller

tianmeng

009

Tanmng Teflon Coated Fan Impeller is designed for industrial environments requiring high corrosion resistance, efficiency, and long-term reliability. Manufactured from premium stainless steel or aluminum alloy and treated with advanced PTFE coating technology, this impeller delivers stable airflow performance and reduced maintenance costs. It is widely used in industrial ventilation, HVAC systems, marine engineering, and chemical processing. Contact Tanmng today to get a customized solution and competitive quotation.

| Parameter | Description / Options |

|---|---|

| Impeller Type | Centrifugal / Axial / Custom Design |

| Material | Stainless Steel 304 / 316 / 316L / Aluminum Alloy |

| Blade Design | Backward-curved / Forward-curved / Radial |

| Operating Temperature | Up to 260°C |

Advanced Teflon Coating Protection

The high-performance PTFE coating effectively resists corrosion, scaling, and abrasion, making the impeller ideal for chemical, marine, and high-humidity environments while reducing maintenance frequency.

High-Efficiency Aerodynamic Design

Optimized blade geometry increases airflow and static pressure under the same power consumption, helping customers achieve energy savings and stable operation.

Multiple Material Options

Available in stainless steel and aluminum alloy to meet different strength, corrosion resistance, and weight requirements across various industrial systems.

Precision Dynamic Balancing

Each impeller undergoes strict dynamic balancing to minimize vibration, ensure smooth operation, and extend the service life of bearings and fan systems.

OEM & Custom Manufacturing Support

Tanmng supports drawing-based customization, sample development, and small-batch production to meet OEM and project-based requirements.

Industrial Ventilation Systems – Factory exhaust, dust removal, and high-temperature air handling

HVAC Systems – Commercial and industrial air supply and return systems

Marine & Ship Engineering – Ventilation systems resistant to salt spray and humid environments

Chemical Processing Plants – Handling corrosive gases and chemical vapors

Power & Energy Facilities – Boilers, cooling systems, and power plant ventilation

Q1: What environments are Teflon coated fan impellers suitable for?

A: They are suitable for corrosive, high-humidity, and abrasive environments such as chemical plants, marine applications, and industrial exhaust systems.

Q2: Can you provide customized sizes and designs?

A: Yes. Tanmng offers OEM/ODM services and can customize dimensions, blade types, and coatings based on drawings or operating conditions.

Q3: Does the Teflon coating affect fan efficiency?

A: No. Properly controlled coating thickness can reduce surface friction and help maintain stable long-term efficiency.

Tanmng Teflon Coated Fan Impeller is designed for industrial environments requiring high corrosion resistance, efficiency, and long-term reliability. Manufactured from premium stainless steel or aluminum alloy and treated with advanced PTFE coating technology, this impeller delivers stable airflow performance and reduced maintenance costs. It is widely used in industrial ventilation, HVAC systems, marine engineering, and chemical processing. Contact Tanmng today to get a customized solution and competitive quotation.

| Parameter | Description / Options |

|---|---|

| Impeller Type | Centrifugal / Axial / Custom Design |

| Material | Stainless Steel 304 / 316 / 316L / Aluminum Alloy |

| Blade Design | Backward-curved / Forward-curved / Radial |

| Operating Temperature | Up to 260°C |

Advanced Teflon Coating Protection

The high-performance PTFE coating effectively resists corrosion, scaling, and abrasion, making the impeller ideal for chemical, marine, and high-humidity environments while reducing maintenance frequency.

High-Efficiency Aerodynamic Design

Optimized blade geometry increases airflow and static pressure under the same power consumption, helping customers achieve energy savings and stable operation.

Multiple Material Options

Available in stainless steel and aluminum alloy to meet different strength, corrosion resistance, and weight requirements across various industrial systems.

Precision Dynamic Balancing

Each impeller undergoes strict dynamic balancing to minimize vibration, ensure smooth operation, and extend the service life of bearings and fan systems.

OEM & Custom Manufacturing Support

Tanmng supports drawing-based customization, sample development, and small-batch production to meet OEM and project-based requirements.

Industrial Ventilation Systems – Factory exhaust, dust removal, and high-temperature air handling

HVAC Systems – Commercial and industrial air supply and return systems

Marine & Ship Engineering – Ventilation systems resistant to salt spray and humid environments

Chemical Processing Plants – Handling corrosive gases and chemical vapors

Power & Energy Facilities – Boilers, cooling systems, and power plant ventilation

Q1: What environments are Teflon coated fan impellers suitable for?

A: They are suitable for corrosive, high-humidity, and abrasive environments such as chemical plants, marine applications, and industrial exhaust systems.

Q2: Can you provide customized sizes and designs?

A: Yes. Tanmng offers OEM/ODM services and can customize dimensions, blade types, and coatings based on drawings or operating conditions.

Q3: Does the Teflon coating affect fan efficiency?

A: No. Properly controlled coating thickness can reduce surface friction and help maintain stable long-term efficiency.