Views: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

In modern manufacturing, the performance and longevity of components often hinge on the quality of surface coatings. Thermal Spray Equipment is an essential solution for achieving these high-performance surfaces, capable of enhancing wear resistance, corrosion protection, thermal insulation, and chemical stability across a wide range of industrial applications. At Jinan Tanmng New Material Technology Co., Ltd., we provide state-of-the-art thermal spraying systems including arc, supersonic, plasma, and ultra-high-speed laser cladding lines, supported by over 40 sets of imported high-end thermal spraying equipment and 50 high-precision machining units. These systems ensure precise deposition, consistent coating properties, and exceptional surface quality. Understanding which materials and powders are most compatible with thermal spray equipment is critical for engineers, researchers, and coating specifiers seeking to optimize the performance, reliability, and cost-effectiveness of their components.

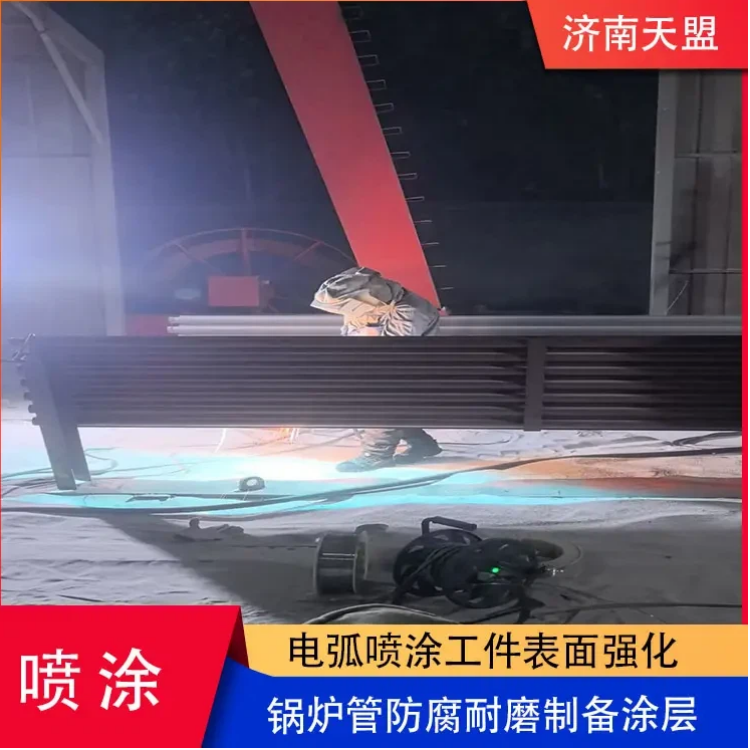

Thermal spray technology is not merely about applying a layer of material on a substrate; it is a science of combining equipment capabilities, powder characteristics, and process parameters to achieve designed functional properties. Whether it is reinforcing paper machine rolls, protecting high-strength petrochemical components, or extending the service life of industrial boilers, selecting the right feedstock and process combination is paramount. This article provides a comprehensive guide to the materials and powders best suited for thermal spray equipment, examining their characteristics, processing considerations, and application-specific performance outcomes.

Thermal spraying accommodates a wide spectrum of feedstock materials, each tailored to meet specific engineering and operational requirements. The correct feedstock ensures not only optimal coating performance but also maximizes the lifespan and efficiency of equipment in service.

Metallic powders and alloys are the backbone of many thermal spray applications. Cermets, which are ceramic-metal composites, are engineered for exceptional wear resistance and are particularly effective in high-friction environments. Nickel and cobalt-based alloys offer excellent high-temperature stability and corrosion resistance, making them ideal for components exposed to aggressive chemical or thermal environments. Stainless steel powders provide a combination of corrosion resistance, mechanical strength, and adhesion, making them widely used in petrochemical and energy sectors.

The choice of metal alloy powder impacts not only performance but also the application process. Supersonic spraying systems, for instance, accelerate particles to extremely high velocities, promoting strong adhesion and low porosity, which is critical for components such as pumping rods, drill pipes, and press rolls. Arc spraying, on the other hand, can deliver high deposition rates and is often used for large industrial surfaces where volume coverage is important. The proper pairing of metal alloy feedstocks with the appropriate thermal spray equipment ensures both efficiency and coating reliability.

Ceramic powders, including zirconia and alumina, are widely recognized for their thermal insulation, hardness, and wear resistance properties. When combined with metallic binders to form composite powders, these coatings balance hardness and toughness, making them suitable for both high-stress mechanical components and heat-sensitive applications.

Plasma spray equipment excels at processing ceramic powders due to its high-energy plasma arcs, which can completely melt and project ceramic particles onto a substrate, forming a dense and highly adherent layer. This is critical for applications such as turbine blades, combustion chamber liners, engine components, and electrical insulators, where both thermal stability and mechanical strength are essential. Composite powders also allow for customization of properties, enabling coatings that can resist thermal cycling while maintaining wear resistance under mechanical stress.

Thermal spray systems may utilize wire-fed or powder-fed feedstocks, each with distinct advantages. Wire-fed systems typically provide high deposition efficiency and are less prone to waste, which is beneficial for coating large industrial rolls, pipelines, or tanks. They are particularly effective for high-volume applications and allow continuous spraying without frequent material replacement.

Powder-fed systems, by contrast, offer greater versatility in material selection, particle size control, and composition adjustment. These systems are indispensable for applications requiring precise coating properties, such as aerospace components, medical implants, and high-performance industrial equipment. Understanding the limitations and strengths of wire versus powder feedstocks enables engineers to match equipment capabilities to project requirements, optimizing both performance and cost-effectiveness.

The physical characteristics of powders—often referred to as powder morphology—play a decisive role in determining coating quality, consistency, and functional performance. Differences in particle shape, size distribution, and melting behavior can lead to variations in deposition efficiency, porosity, surface finish, and mechanical properties.

Uniform particle size distribution is critical for ensuring smooth powder flow through the feeding system and consistent deposition on the substrate. Fine powders tend to create smoother, denser coatings with minimal porosity but require precise feeding mechanisms to prevent clogging or inconsistent delivery. Coarser powders, while easier to feed, may result in rougher surfaces and higher porosity.

Flowability is influenced not only by particle size but also by particle shape. Spherical powders generally flow more easily and melt uniformly, whereas irregularly shaped powders may require specialized feed equipment or additional pre-processing. The melting behavior of the powder determines the required thermal energy for achieving optimal deposition. Powders must reach a semi-molten or molten state to form strong metallurgical bonds with the substrate. Matching equipment parameters—such as spray temperature, particle velocity, and nozzle geometry—to powder characteristics is essential to achieving high-performance coatings.

Maintaining powder quality from delivery to application is crucial. Exposure to moisture, contamination, or oxidation can degrade powder properties, resulting in poor adhesion, increased porosity, or inconsistent coating thickness. Controlled storage conditions, careful handling, and periodic quality inspections are standard best practices to ensure consistent results. At Jinan Tanmng New Material Technology Co., Ltd., powders are stored in controlled environments and carefully tracked to maintain optimal performance, reducing the risk of coating defects and production delays.

Selecting the right combination of feedstock and spraying process is critical for achieving the desired coating properties. The same material can yield vastly different results depending on the method and equipment used.

High-Velocity Oxygen Fuel (HVOF) spraying, combined with tungsten carbide-cobalt (WC-Co) powders, is the gold standard for wear-resistant coatings. The HVOF process propels particles at supersonic speeds, producing dense, low-porosity coatings with exceptional hardness. Components such as plungers, pumping rods, and drill pipes, which are subjected to high abrasion and mechanical stress, benefit greatly from WC-Co coatings, achieving significantly extended service life and reduced maintenance frequency.

Plasma-sprayed ceramic coatings, such as zirconia stabilized with yttria, provide highly effective thermal barriers. These coatings are essential for protecting metal substrates in high-temperature environments, such as turbine blades, combustion chambers, and industrial furnaces. The plasma spray process ensures complete melting and proper bonding of ceramic particles, resulting in coatings that withstand thermal cycling, minimize heat transfer, and enhance component longevity.

Arc and flame spray processes are widely used to apply corrosion-resistant metallic coatings. Nickel, cobalt, and stainless-steel alloys are commonly applied to protect components exposed to harsh chemicals, marine environments, or high-temperature oxidative conditions. By controlling process parameters such as temperature, spray distance, and particle velocity, dense, uniform coatings with excellent adhesion are achieved. These coatings prevent material degradation, extend service life, and maintain operational efficiency in critical industrial applications.

Even the best feedstock cannot achieve optimal performance without precise control over the thermal spray process. Equipment capabilities, parameter settings, and monitoring protocols play a decisive role in coating quality.

Temperature, particle velocity, standoff distance, and spray angle directly affect coating density, porosity, and adhesion. Small deviations in these parameters can result in uneven coatings, reduced performance, or increased wear. Advanced thermal spray equipment from Jinan Tanmng New Material Technology Co., Ltd. allows operators to finely tune all critical parameters, ensuring reproducible results across different component geometries and materials.

To ensure consistent coating quality, modern thermal spray operations incorporate in-line monitoring of key parameters such as particle temperature, velocity, and deposition rate. Post-coating inspection includes adhesion testing, porosity measurement, hardness testing, and microstructural analysis. These steps are vital for confirming that coatings meet stringent industrial requirements, particularly for high-value applications in aerospace, petrochemical, and power generation sectors.

Compatibility between thermal spray equipment and premium powders enhances coating quality, reduces waste, and improves overall process efficiency. Systems capable of handling a wide range of metals, ceramics, and composite powders allow engineers to fine-tune coatings for specific performance requirements. Optional process tuning and optimization services further ensure that each coating achieves the desired mechanical, thermal, and chemical properties, making it easier to deliver consistent, high-specification results.

Understanding the interplay between materials, powders, and equipment is critical to maximizing the potential of Thermal Spray Equipment. Jinan Tanmng New Material Technology Co., Ltd. offers versatile, high-precision systems that accommodate a wide array of powders and materials, ensuring coatings meet the most demanding industrial standards. From wear-resistant WC-Co coatings to thermally insulating ceramics and corrosion-resistant metallic layers, our equipment and process expertise deliver reliable, high-performance results. For further inquiries or to discuss your specific coating requirements, contact us today and explore our advanced thermal spray solutions.

Q1: What powders are most suitable for thermal spray equipment?

A1: Metallic alloys (Ni, Co, stainless), cermets, ceramics (zirconia, alumina), and composite powders are commonly used, chosen based on wear, thermal, or corrosion requirements.

Q2: How does powder morphology impact coating quality?

A2: Particle size, shape, and melting characteristics affect flow, deposition consistency, adhesion, and surface finish. Optimized powders are essential for uniform, high-quality coatings.

Q3: Which process is best for wear-resistant coatings?

A3: HVOF spraying with WC-Co powders produces dense, low-porosity coatings ideal for high-abrasion industrial components.

Q4: Why is equipment compatibility with premium powders critical?

A4: Properly compatible equipment ensures precise powder delivery, reduces waste, and achieves high-quality coatings for critical industrial and high-specification applications.

content is empty!

content is empty!